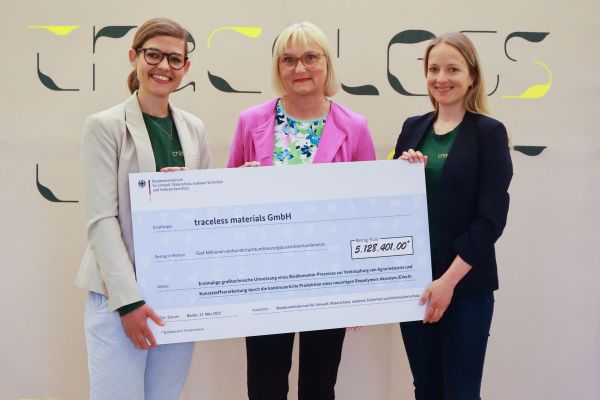

The startup traceless materials has developed a plant-based plastic alternative. The company is planning to set up a demonstration plant in Hamburg to implement the technology on an industrial scale for the first time. The project is now being funded with around 5 million euros from the Federal Environment Ministry's (BMUV) Environmental Innovation Program. At a press event, Parliamentary State Secretary Dr. Bettina Hoffmann handed over the symbolic funding check to the company's two founders, Anne Lamp and Johanna Baare.

traceless is environmentally friendly and versatile

traceless materials produces a natural biomaterial as an alternative to plastic from plant residues from grain processing. The traceless® material is completely bio-based, home-compostable and plastic-free. The patent-pending technology is based on natural polymers, comes without potentially harmful substances and has a minimal environmental footprint: compared to plastic, 91% of CO2 emissions and 89% of fossil energy demand is saved during production and disposal. The material is produced in the form of a granulate that can be further processed using standard technologies in the plastics and packaging industry. Thus, the material can be used in a wide range of end products - from rigid molded parts and flexible films to paper coatings or adhesives.

Founded in 2020, the company has already implemented the technology on a pilot scale. With the aim of replacing plastics in large quantities soon, production capacities will be expanded to industrial scale. The planned plant will demonstrate for the first time that the innovative process can be implemented on an industrial scale. In parallel with the technology scaling, the team of over 30 is developing pilot products from the traceless material with its customers and partners.

"The experts from the Ministry of the Environment and the Federal Environment Agency have comprehensively examined whether our technology actually contributes to environmental protection. The funding approval is a great confirmation of this."