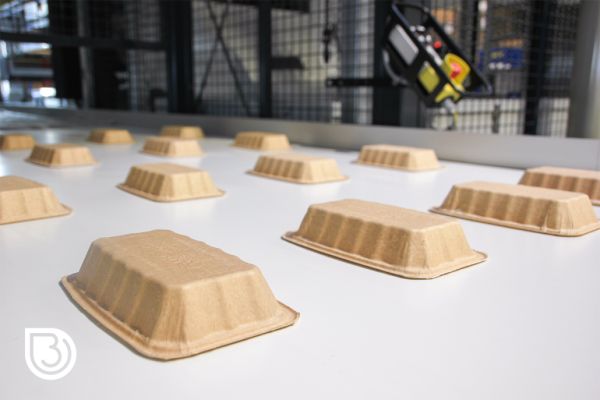

Hamburg-based startup BIO-LUTIONS has joined forces with Swedish company PulPac and machine suppliers to develop a production technology that will be used in BIO-LUTIONS' new factory in Schwendt/Oder from summer 2022. The company's goal is to replace plastic products with those made from natural materials.

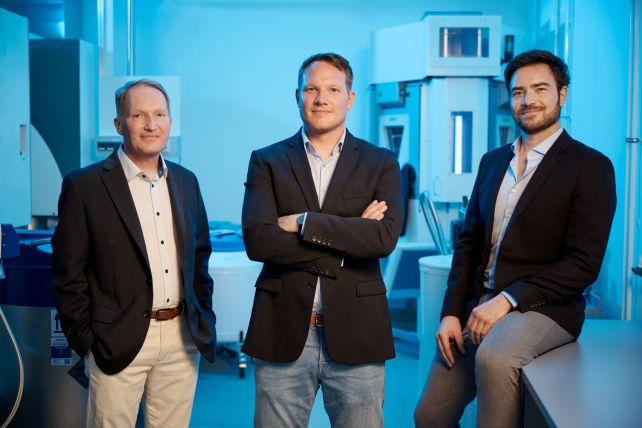

BIO-LUTIONS was founded in 2017 by Eduardo Gordillo and Stefan W. Dircks. The company has co-developed a patented technology that makes it possible, for example, to produce packaging for fruits and vegetables and disposable tableware from a variety of agricultural residues without additional binders or chemicals. The collaboration with PulPac opens the door to an additional production process for fiber molding, the Dry Molded Fiber technology.

Up to 80% less CO2 with new process

The process saves significant amounts of water and energy, resulting in up to an 80% lower CO2 footprint compared to conventional methods. The process is extremely fast and more efficient than conventional fiber molding methods. While Dry the Molded Fiber technology will not be used for all of BIO-LUTIONS' products, it offers significant benefits for a variety of disposable products.

The cooperation with PulPac and the opening of the new production facility represent important milestones in the startup's development. They also include the closing of a Series A financing round in May 2019 for 8.3 million euros and a Pre-Series B round in February 2021 for 2.7 million euros.