Internet of Things, Industry 4.0, machine-to-machine communication - these are all buzzwords that come up frequently, but only a few can fill them with life. One of them is the Hamburg-based startup Cybus, which was quick to recognize the trend towards digitization in industrial production. Just like the crucial role played by comprehensive data analysis. The financing round of 8 million euros completed this year is a clear sign of the success of this idea.

Sailing on the Alster - it's a essential part of the Hamburg lifestyle. But only very few people can afford their own boat. In 2011, the sharing economy was just taking off, the business idea of no longer owning goods just for yourself but sharing them with others. Why shouldn't that also work with sailboats? That's how the startup bootschaft.net was born, with the plan to make boat sharing big in Germany.

Four years later, the founders had to admit: Unfortunately, the idea did not work. But as it is so often the case in the startup world, the end also meant the beginning of something far more successful. At bootschaft.net, a device was utilized that made use of the MQTT network protocol. The abbreviation stands for Message Queuing Telemetry Transport and the protocol enables the transmission of telemetry data in the form of messages between devices. In our specific case, this made it possible to determine where exactly the boats were at any given time.

This technology leads right into the Internet of Things, in which a wide variety of devices and machines can communicate with each other. A development that Peter Sorowka, Marius Schmeding and Pierre Manière from bootschaft.net wanted to benefit from when they launched their "Internet of Things Enabler Kit" in 2014. That didn't exactly prove to be a big seller, but in 2015 it led to the founding of their startup that would finally bring success: Skybus.

The team made its first big appearance in September 2015 at the Startups@Reeperbahn pitch by Hamburg Startups. There, they had to realize that their business idea and their product still needed some explaining; some jury members admitted that they didn't understand everything. At least they won the audience award. The year also brought another lesson that many startups need to learn: Be careful when choosing a company name! A large media company sensed a risk of confusion, so the company changed its name to Cybus. That's what it’s called until today.

A series of financing rounds brought Cybus millions

In the following years, Cybus went steadily uphill. In 2016, Andreas Pfannenberg became the first investor. He is the managing director of Pfannenberg Group Holding GmbH, a Hamburg-based company for air conditioning technology. In 2017, Schunk GmbH & Co, world market leader for gripping systems and clamping technology, joined in another round of financing. At the time, a campaign with the peculiar title "Make your device great again" had attracted attention.

The legacy investors were involved again in 2019, when a seven-figure sum went to Cybus. However, the venture capital firm btov Partners with its Industrial Technologies Fund was the lead investor here. At the time, Cybus was only the second company to be financed by the fund, which specializes in hardware and software solutions relevant to industrial production.

If this financing round was already a real milestone for the startup, this is even more true for the latest coup from spring 2022, when Cybus was able to announce an investment of 8 million euros. The already committed individuals and companies were now joined by the investment company PwC Holdings Germany GmbH, the former CEO of Dürr AG Ralf Dieter and the former Siemens CEO of the Factory Automation Business Unit Ralf-Michael Franke.

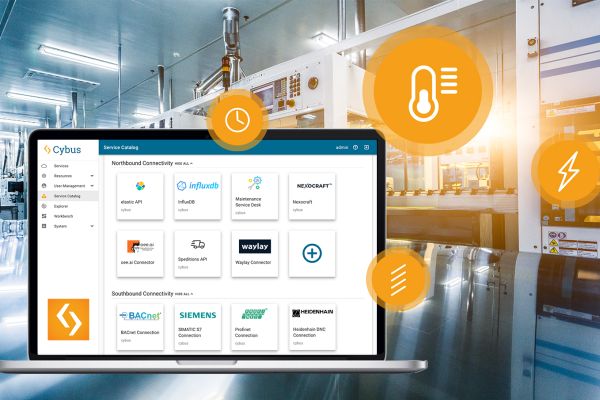

So, what makes the parties involved, some of whom are also Cybus customers, invest millions? It's a software called Connectware, which enables industrial companies to collect and analyze data. "We are building the data highway for companies," is how CEO Peter Sorowka sums up the basic idea.

Described in a bit more detail: Cybus provides a solution for the digitalization of industrial manufacturing with its smart factory software. A smart factory is characterized by production conditions in which all relevant information is available and usable through comprehensive networking. The analysis of this information enables companies to continuously increase the efficiency and quality of their production processes. The software from Cybus connects production and IT systems with each other, independent of manufacturers, and in many cases complements existing programs. Even companies with a high level of in-house software expertise, such as Siemens or Amazon, can benefit from this.

Data security, an essential criterion especially in Germany, is according to Cybus also guaranteed. An integrated security solution ensures that factories retain unrestricted data sovereignty and production downtimes are avoided. Independent of cloud or other third-party providers, companies can digitize their manufacturing independently with the software.

Cybus is particularly strong in the automotive industry. Porsche, for example, was acquired as a customer, which in turn fueled the decision for the current financing round. What makes Cybus so attractive for investors is the fact that just a few large customers can provide the desired scaling effects. The startup is long past the pilot project phase. In the meantime, the digitization of entire factories is on the agenda. This is what is meant by the term Industry 4.0.

Companies cannot avoid such processes if they want to remain competitive in the long term. And Cybus wants to make them even more convenient for its customers in the future. The planned further development of the software will simplify usability and significantly reduce training time. Connectware will also become attractive for smaller and medium-sized companies.

By now, the Cybus team consists of 33 people. As is now common for software companies and accelerated by the Corona pandemic, the employees are spread over several locations in Germany and abroad and the team members come from the most diverse countries, from Portugal to Brazil to India. The company headquarters, however, is and remains in Hamburg.

The idea of founding a startup in 2015 obviously paid off; the gut feeling of betting on MQTT was not wrong. It didn't matter much that none of the founders had seen the inside of a factory at that time. However, this led to the fallacy that factories were already somehow connected. This was obviously not the case, so Cybus changed its focus and found its current model of success.